With the right incineration system, waste incineration has become safer and more sustainable than ever. The key to proper incineration is having a primary chamber that incinerates waste at temperatures up to 1130°C and a secondary after-chamber treating the resulting emissions for a minimum of 2 seconds at temperatures up to 1150°C (depending on the type of waste being incinerated), which is guaranteed on Addfield Incinerators. In countries with strict emissions regulations such as the United Kingdom, Addfield supply additional filtration systems such as Venturi Wet Scrubbers and Ceramic Filtration with Acid Scrubbers to drastically reduce harmful emissions such as Dioxins, Furans, and Dust. The results of the incineration process are sterile ash and clean emissions that adhere to the strictest regulations. You may find more about our filtration systems here: https://www.valmena.com/filtration-and-monitoring.php

Each type of waste must have a specific type of incinerator. The reason behind this lies in the composition of the waste such as energy, moisture, and shape and volume of the administered material. A main value in Addfield incinerators is having unique designs for each type of waste that vary in internal chamber architecture, temperatures, and waste input mechanisms. For example, animal and aquaculture incinerators must be designed differently since fish waste is much higher in moisture and stacks up more in the primary chamber; medical and municipal waste incinerators are also different since specific temperatures are required for each type of waste to ensure the resulting emissions are clean and safe. You may find all the types of incinerators we offer here: https://www.valmena.com/incineration.php

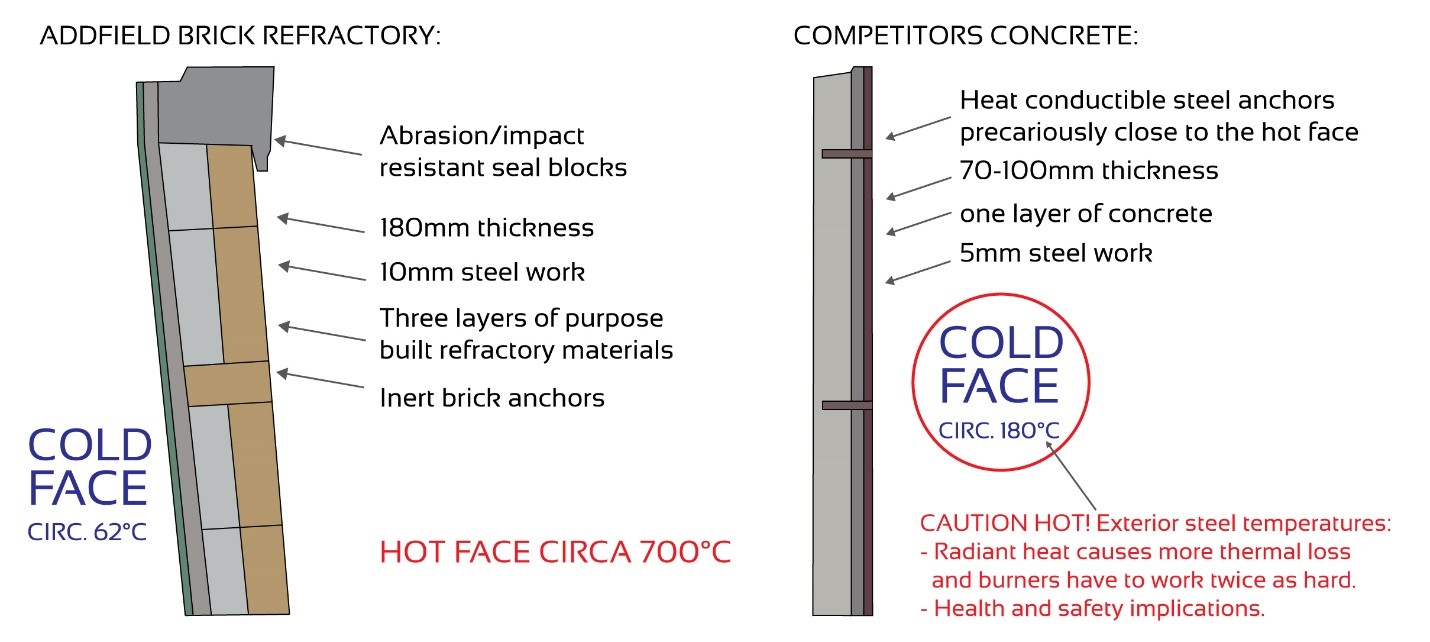

To guarantee internal chamber temperatures, thermal efficiency, and better fuel consumption, Addfield use brick refractory instead

of the conventional concrete used by all competitors which differentiates Addfield from all other manufacturers.

The use of brick reduces heat losses which in turn makes the incineration process faster, more efficient, and requires less fuel.

This crucial characteristic makes Addfield incinerators 40% more efficient than any other incinerator on the market.

Another value in brick refractory is the increased lifespan it gives to the incinerator. Concrete refractory used by competitors

tend to crack early on and eventually shatter inside the incinerator, which would require servicing and in turn decreases the incinerator’s efficiency.

Brick refractory, on the other hand, lasts more than 10 years before requiring maintenance. In the event of a brick failure,

the respective brick piece would be easily removed and replaced by a new one without compromising the whole refractory lining.

First, the emission standards in the region where the incinerator is to be installed must be checked. Regulations might require equipping incinerators with emissions filtration and monitoring systems. Depending on the limits of each emission parameter, the respective filtration system will be required such as Venturi Wet Scrubbers, Ceramic Filtration Systems, etc. Regulations might also require Constant Emissions Monitoring System (CEMS) to monitor emissions continuously. After taking care of emissions, you may consider looking for recommended options such as automatic bin tippers and ram loaders for continuous input of waste and ease of work.

Every day, hospitals generate hazardous waste such as syringes, tubes, and vials that have been in contact with toxic chemical agents which have specific forms of handling and disposal. According to WHO, for example, cytotoxic waste can only be disposed of through incineration at high temperatures in incinerators equipped with secondary after-burners that guarantee a residence time of 2 seconds. With that being said, Addfield has become the go-to manufacturer of medical incinerators for the NHS, UN, and many other entities with strict emission standards. Check our latest, most advanced installation for an NHS hospital in the UK here: https://addfield.com/case-studies/the-uk-most-advanced-clinical-waste-to-energy-plant-for-the-nhs/

To comply with the WHO and Waste Incineration Directive (p. 81), temperatures of 800°C to 900°C must be achieved to eliminate all combustible materials in a controlled manner. The result is clean, sterile ash that can be disposed of in a landfill. In the case of medical waste containing needles and surgical tools, the metals and glass will remain after incineration yet will be sterile due to the temperatures achieved. It is important to note that in medical waste incineration, the ash will not contain heavy metals, such as mercury, as long as the input waste doesn’t (such as thermometers).

Usually, waste is collected in the relative bags. These bags are put into bins and which are transported to the incinerator. The bins get tipped over the incinerator’s input and their contents are emptied. So, the bins do not need to be incinerated. Sometimes, the bags leak inside the bins and this is why it is recommended to wash the bins periodically with hot water or steam.